LNG Modules for Canada

The LNG Canada project concerns the supply of turbo compressors for Shell’s liquefied natural gas plant in Kitimat (Canada). The programme entails an initial export of 6.5 tonnes of natural gas per year while the first shipment of LNG from the Kitimat terminal is expected within the first six months of 2023.

key info

In detail

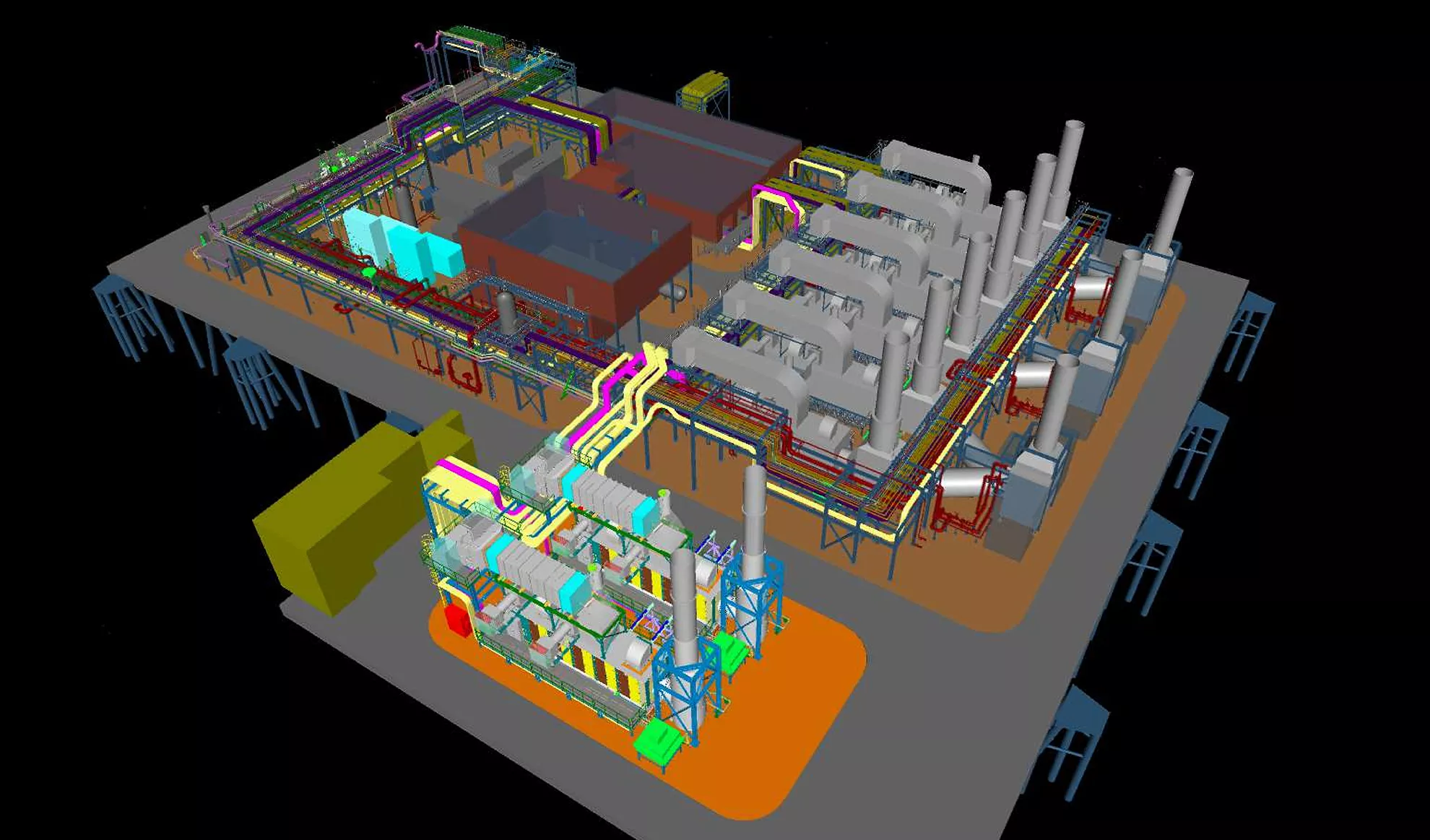

The Renco engineering sector works with BIM (Building Information Modelling), a digital information system consisting of the 3D model integrated with the building’s physical, performance and functional data. The Renco BIM software programme can generate virtual 3D models and visualise every aspect linked to the design. It devises a plant programming, design, construction and maintenance process using an information model incorporating all information relating to the plant’s entire life cycle, including the design, construction and decommissioning phases.

Focus on the details

CLOSE-UP ON THE PROJECT

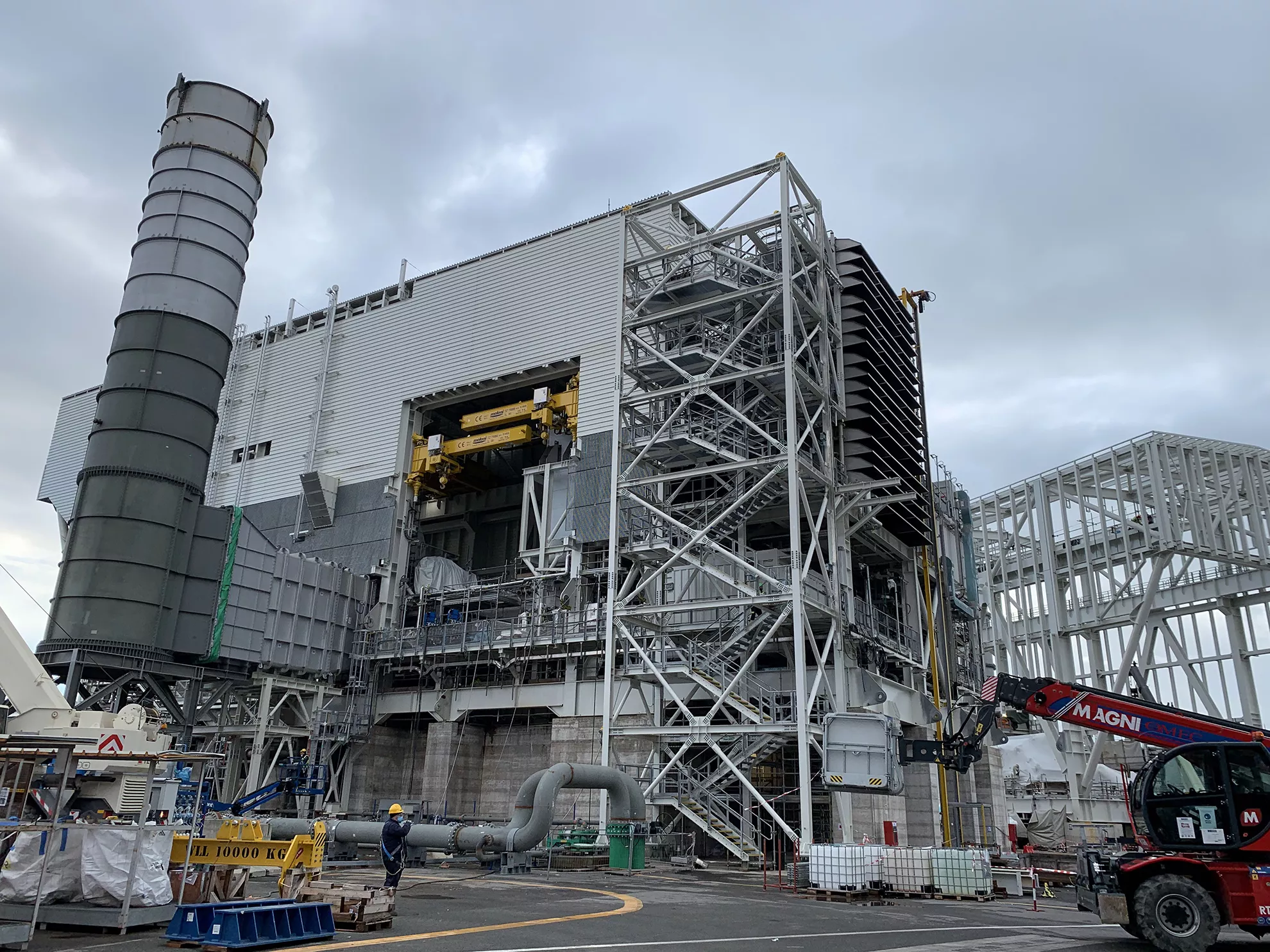

The construction of four modules, which lasted less than 20 months, involved all Cimolai plants in the Friuli region, in particular the one in San Giorgio di Nogaro (Udine) where the structures were assembled.

The contract involves the supply of four modules for two compression trains, each of which will be equipped with two LMS100-PB turbines – deriving from the aeronautical sector – and two centrifugal compressors.