Maintenance of the LNG plant in Oman

In recent years Renco has chosen to boost its Operation & Maintenance services in favour of large companies. This activity is characterised by long-term contracts. Among the expanding areas of this business line, special attention was devoted to the Middle East area (Oman, Qatar, Saudi Arabia, Bahrain and Iraq). The first work involving maintenance and the increase of the production capacity was completed in the liquid natural gas (LNG) plant in southern Oman.

key info

In detail

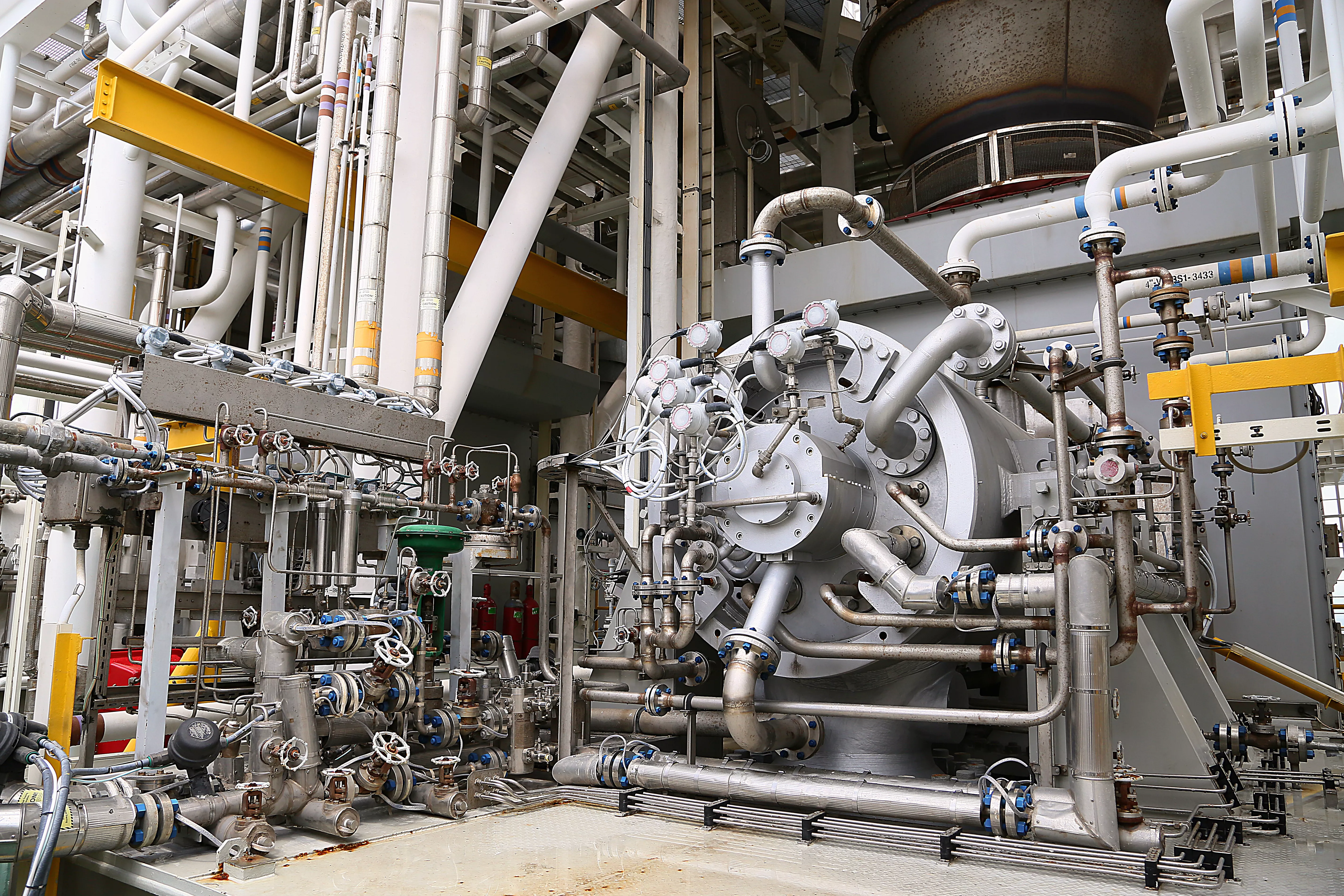

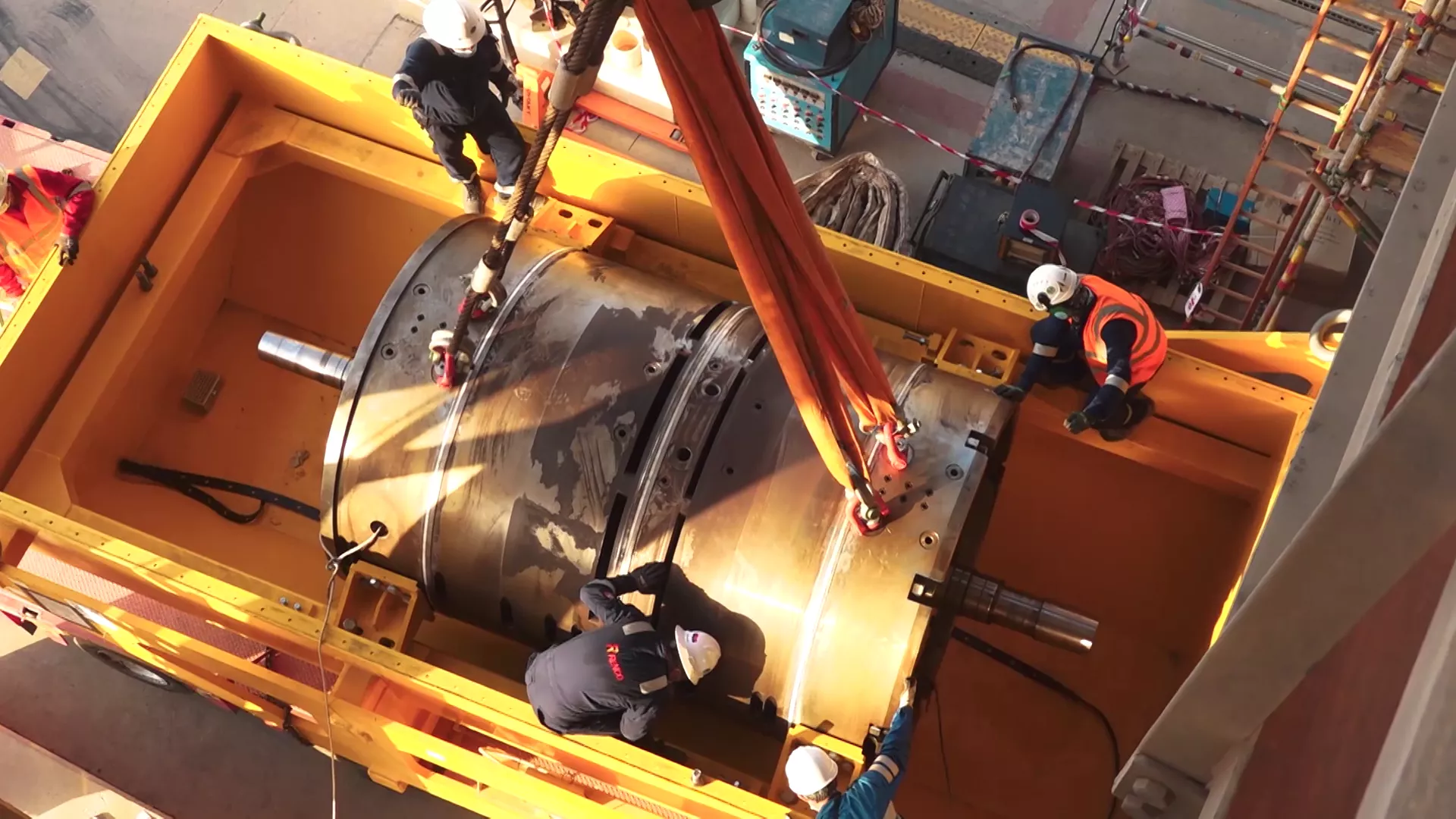

Renco participated on behalf of Baker Hughes in a debottlenecking project in the LNG plant located in Sur, Oman. The project is aimed at expanding the site’s production capacity so that it can commercialise a greater amount of LNG. The production increase is guaranteed through the updating and modification of machinery obtained through a 28-day scheduled shutdown on each production line.

Focus on the details

CLOSE-UP ON THE PROJECT

Renco participated with its own specialised workforce (around 450 people) and equipment in performing maintenance on 2 of the plant’s 3 production lines in two distinct phases, the first in September 2021 and the other in September 2022, guaranteeing safely executed works, high quality and quicker completion times. The company received formal appreciation for its activities both by the principal, Baker Hughes, and by the end client and owner of the plant, Oman LNG.

It was the first project of this size and type completed by Renco in the Middle East, which helped to strengthen the partnership with a strategic client such as Baker Hughes.